Buy with this product

794 bought

ID: 2145

244 с

-5%

6751 bought

ID: 3678

288 с

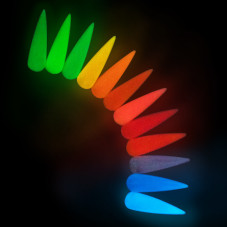

584 bought

ID: 5263

103 с

122 bought

ID: 13087

61,62 с

509 bought

ID: 14591

61,62 с

Similar products

509 bought

ID: 14591

61,62 с

70 bought

ID: 6738

61,62 с

72 bought

ID: 13093

61,62 с

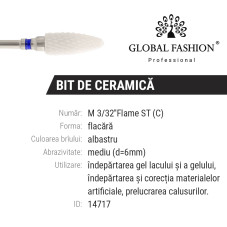

73 bought

ID: 14717

61,62 с

16 bought

ID: 21823

61,62 с

122 bought

ID: 13087

61,62 с

9 bought

ID: 24626

61,62 с

Ceramic Tip, Rounded Cone, Red Cut: Exploring the Benefits of Ceramic Nozzles for Milling Cutters Milling cutters require a high level of precision to achieve the desired outcome, and the type of nozzle used can make a significant difference in the results. Ceramic nozzles are gaining popularity as they offer a superior level of precision and wear resistance compared to traditional metal nozzles. In this article, we will explore the benefits of ceramic tips, rounded cones, and red cuts for milling cutters. Ceramic tips are a popular choice for milling cutters due to their high hardness and wear resistance. Ceramics are much harder than metals, which means they can withstand the high temperatures and abrasive environments that milling cutters are exposed to. Ceramic tips are also less likely to corrode or break down over time, making them a more reliable option. Rounded cones are another popular type of ceramic nozzle used for milling cutters. Rounded cones are often used in applications where a high level of accuracy is required, such as in the aerospace and medical industries. The shape of the rounded cone allows for precise targeting of the milling area, resulting in a more uniform and consistent finish. Red cuts are a specific type of ceramic nozzle that is designed to be used in high-pressure applications. These nozzles are made from a special type of ceramic material that is able to withstand extreme temperatures and stress. The red color of the nozzle is due to the high level of heat resistance that the material possesses. Red cut ceramic nozzles are becoming increasingly popular in industries such as oil and gas exploration, where high pressures and temperatures are commonly encountered. In addition to their superior wear resistance, ceramic nozzles offer several other benefits over traditional metal nozzles. Ceramic nozzles are less likely to cause damage to the surface being milled, as they do not generate as much heat or friction as metal nozzles. This means that ceramic nozzles can be used to mill delicate materials that would be damaged by metal nozzles. Ceramic nozzles are also less likely to clog, which means less downtime and increased productivity. They are also easier to clean and maintain, requiring less frequent replacement than metal nozzles. In conclusion, ceramic tips, rounded cones, and red cuts offer a range of benefits for milling cutters. They are more durable, precise, and reliable than traditional metal nozzles, making them the preferred choice for many applications. If you are looking to improve the quality and efficiency of your milling processes, consider using ceramic nozzles for your milling cutter.

6751 bought

ID: 3678

288 с

3364 bought

ID: 3688

514 с

2343 bought

ID: 1863

341 с

-5%

1501 bought

ID: 11773

205 с

1766 bought

ID: 12137

185 с

-10%

511 bought

ID: 16061

262 с

-15%

406 bought

ID: 18149

192 с

-15%

255 bought

ID: 15998

192 с

-15%

240 bought

ID: 2190

218 с

-15%

196 bought

ID: 11951

205 с

-20%

191 bought

ID: 12047

218 с

-15%